Medical silicone tubing is an essential component widely utilized in the healthcare sector. Its unique properties, such as biocompatibility and flexibility, make it suitable for a variety of medical applications. These tubes are designed to meet stringent standards for performance and quality, ensuring the safe delivery of fluids and gasses to patients.

Given its critical role in patient care, selecting the right silicone tubing requires careful consideration of material properties, manufacturing processes, and compliance with regulatory guidelines. The choices made can significantly impact the effectiveness and safety of medical procedures and devices. So, let’s continue reading and learn how to choose medical silicone tubing!

What Is Medical Silicone Tubing?

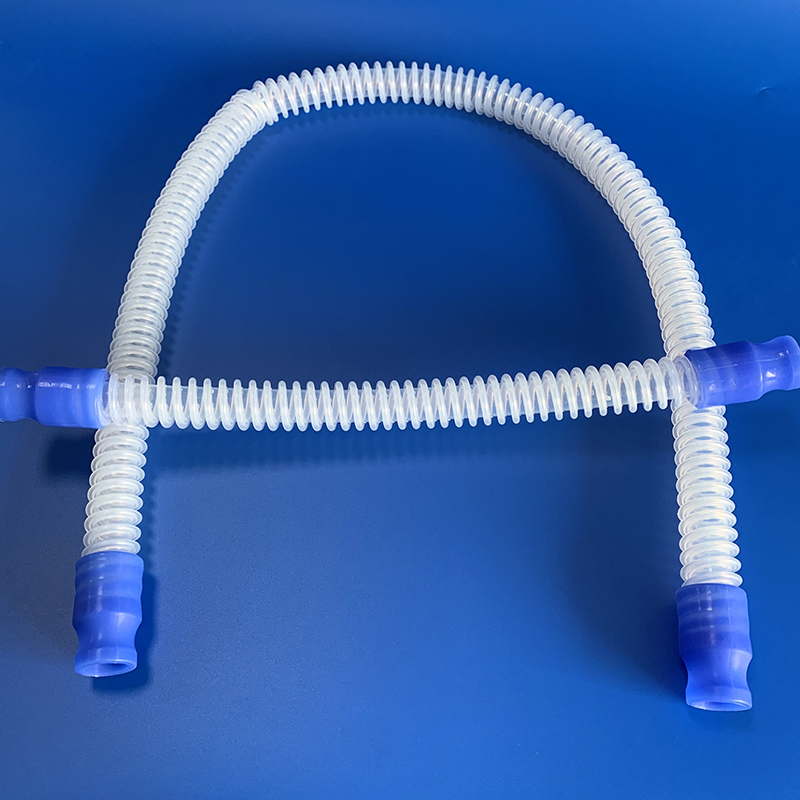

Medical silicone tubing is a type of plastic tubing specifically engineered for medical applications. Composed of silicone elastomers, it exhibits remarkable flexibility, chemical inertness, and temperature resistance. These tubes are often transparent, allowing for easy monitoring of fluid flow, and can be produced in various sizes and shapes to fit diverse medical device applications.

The preferred material for numerous healthcare applications, medical-grade silicone is often chosen for its ability to withstand repeated sterilization and maintain its physical properties over time. Whether used for fluid transfer or as replacement tubing in critical devices, silicone tubing plays an indispensable role in the healthcare industry.

Manufacturers of medical silicone tubing must adhere to strict standards, such as USP Class VI, ensuring that the tubing is safe for human contact. The tubing’s versatility extends to its compatibility with different sterilization methods, including dry heat, ethylene oxide, and injection molding processes, which are crucial for maintaining a sterile environment.

Significance of Silicone Tubing in the Medical Sector

Silicone tubing is integral to a variety of medical tubing applications, from simple fluid management tasks to complex device applications. Its biocompatibility and chemically inert nature make it a safe choice for patient care, while its flexibility ensures that it is less prone to kinking, which can disrupt fluid flow during critical medical procedures.

In the healthcare industry, silicone tubing solutions are valued for their heat resistance and chemical resistance, which allow them to withstand harsh environments and a wide range of medical fluids. The tubing’s tear resistance and ability to maintain its integrity under stress contribute to its reliability in life-saving applications.

Developing a plan for the use of medical silicone tubing involves understanding the needs of specific medical devices and ensuring that the tubing supplier can provide products that meet all regulatory requirements. The right tubing options can improve the efficacy and safety of healthcare applications, making the selection process crucial.

Choosing Medical Silicone Tubing

When selecting medical silicone tubing, it is essential to assess the diverse tubing options available and their suitability for intended medical tubing applications. Factors such as size, flexibility, and material composition must align with the specific requirements of the devices in which they will be used. The following are the main factors which you must consider before choosing medical silicone tubing:

Reliable Medical Silicone Tubing Manufacturer

Identifying a reliable medical silicone tubing manufacturer is critical for ensuring that the tubing meets the necessary quality and performance standards. A reputable supplier will have a robust understanding of the healthcare industry’s demands, offering tubing solutions that are chemically resistant and suitable for a variety of medical applications.

From fluid transfer in catheters to use in surgical drains, the manufacturer’s ability to provide medical tubing materials that can withstand repeated sterilization without degrading is essential. They should offer a range of products, including TPE tubing and platinum-cured silicone, known for their superior properties such as tear resistance and the ability to withstand temperatures encountered in medical environments.

Regulatory Requirements (FDA Compliance)

Medical devices, including silicone tubing, must comply with stringent regulatory requirements set forth by the FDA. Compliance ensures that the tubing is safe for its intended use and meets all necessary performance specifications. Manufacturers are responsible for adhering to these regulations throughout the production process.

Ensuring FDA compliance involves rigorous testing and quality control measures. Medical silicone tubing used in device applications must be rigorously evaluated to ensure it meets the necessary safety and efficacy standards before it can be introduced to the market.

Size and Fit

The size and fit of medical silicone tubing are paramount to its functionality within medical devices. Tubing must be precisely tailored to match the dimensions and tolerances of the equipment it serves, ensuring secure connections and uninterrupted fluid or airflow.

Accurate measurements and a clear understanding of the device’s requirements are necessary to select the appropriate tubing. An ill-fitting tube can compromise the performance of a medical device, making size and fit a top priority in the selection process.

Material Composition

Medical silicone tubing is composed of versatile material that caters to a broad range of applications within the healthcare sector. Its base, industrial-grade silicone, is favored for its biocompatibility and resilience under various conditions.

The composition of the silicone material is crucial, as it directly impacts the tubing’s performance. Manufacturers may modify the silicone formula to enhance certain properties, such as flexibility or tensile strength, to meet the specific needs of medical applications.

Temperature Resistance

Temperature resistance is a critical factor in the selection of medical silicone tubing. The tubing must be able to withstand the extreme temperatures encountered during sterilization processes and in the operating environment without degrading or losing its form.

High-quality silicone tubing can endure a wide temperature range, ensuring reliable performance in both hot and cold environments. This durability makes it an ideal choice for medical applications that require frequent sterilization or exposure to various temperature conditions.

Chemical Compatibility

Chemical compatibility is a non-negotiable aspect when choosing medical silicone tubing. The tubing must resist reactions with medications, bodily fluids, and other substances it may come into contact with during medical procedures.

Ensuring compatibility with a range of chemicals prevents the tubing from breaking down or leaching harmful substances, thereby maintaining the integrity of the fluids being transferred and the safety of the patient.

Flexibility and Durability

The flexibility and durability of medical silicone tubing are crucial attributes that affect its performance. Flexibility ensures that the tubing can navigate through complex pathways without compromising its structural integrity.

Moreover, the tubing’s bend radius must be considered, as it dictates how tightly the tube can be bent without kinking. Tubing with an appropriate bend radius maintains an open lumen for consistent fluid flow, even in challenging configurations.

Air Permeability

The air permeability of medical silicone tubing is a vital characteristic, especially in applications such as catheter tubing, where precise control of gas exchange is required. The tubing walls must be designed to allow for the necessary rate of air permeability without compromising the tubing’s strength.

Additionally, for applications where air permeability is not desired, such as in fluid delivery systems, tubing must be constructed to minimize air ingress and maintain a sealed environment. The choice between different types of tubing, such as silicone or PVC tubing, will be influenced by their respective air permeability properties.

Transparency and Clarity

Transparency and clarity are important properties of medical silicone tubing, particularly in applications where visual monitoring of fluid flow is essential. Naturally translucent silicone allows healthcare professionals to observe the contents and detect air bubbles or contaminants.

This level of transparency supports patient safety by enabling immediate detection of potential issues during medical procedures. The tubing’s visual clarity also facilitates inspections for cleanliness and integrity before and after use.

Pressure Rating

The pressure rating of medical silicone tubing is a critical factor, as it denotes the maximum internal pressure the tubing can withstand without failure. This rating is essential for applications where the tubing must maintain integrity under high-pressure conditions, such as in infusion therapies.

When choosing tubing, healthcare providers must ensure the pressure rating exceeds the medical device’s operational requirements to prevent ruptures or leaks that could compromise patient safety.

Manufacturers typically specify the pressure rating for their products, and this must align with the intended medical application. The strength of the tubing walls contributes to its pressure resistance, and selecting tubing with an appropriate wall thickness is paramount for its safe and effective use in high-pressure scenarios within clinical settings.

Sterilizability

Sterilizability is an indispensable aspect of medical silicone tubing, which must undergo rigorous sterilization processes to eliminate microbial contamination. Silicone’s ability to withstand high temperatures and harsh sterilizants makes it ideal for repeated sterilization cycles.

Silicone tubing must endure the specific sterilization methods required, such as autoclaving, ethylene oxide gas, or gamma radiation, without degrading in quality or performance.

When selecting silicone tubing, the material’s compatibility with different sterilization techniques must be considered. Tubing that can be effectively sterilized ensures patient safety and extends its usable life, making it a cost-effective solution for medical facilities that demand high standards of hygiene and cleanliness.

Kink Resistance

Kink resistance is an essential attribute for catheter tubing, as kinks can cause blockages or restrict fluid flow, leading to potential complications during medical treatments.

High-quality silicone tubing is designed to resist kinking, even when bent or manipulated. This resilience ensures uninterrupted flow and consistent performance, which is particularly vital in applications such as dialysis or surgical procedures.

While evaluating kink resistance, healthcare professionals should consider the application’s dynamic conditions and choose tubing with a proven track record of maintaining its shape and functionality.

The flexibility and memory properties of the silicone material contribute to its ability to spring back to its original form after being twisted or bent, helping to safeguard against kinks during clinical use.

Cost

Cost considerations play a significant role in choosing medical silicone tubing, as budgets often dictate the options available to healthcare institutions. While silicone tubing can be more expensive than other materials, its durability and long lifespan can provide a better return on investment over time. Decision-makers must balance initial costs with the tubing’s expected performance and longevity to ensure cost-effectiveness.

In addition to the purchase price, the total cost of ownership, including maintenance, sterilization, and replacement frequency, should be evaluated. Medical silicone tubing that requires less frequent replacement due to its superior quality can offer long-term savings, despite a higher upfront cost. Providers must weigh these factors carefully to make a financially prudent choice.

Customization Options

Customization options for medical silicone tubing are vital for meeting the specific needs of various medical applications. Manufacturers offer customizable solutions that can include variations in diameter, wall thickness, length, and even color coding for easy identification.

Custom features can also accommodate unique requirements, such as embedded radiopaque stripes for X-ray visibility or surface treatments for improved biocompatibility.

When selecting silicone tubing, healthcare providers should assess the availability and scope of customization from manufacturers. Tailored solutions not only enhance the functionality of medical devices but also contribute to better patient outcomes by ensuring that the tubing seamlessly integrates with the medical procedure’s particular demands.

Wrap-Up!

In the realm of medical equipment, selecting a tubing material that meets application requirements is crucial for ensuring patient safety and the effectiveness of medical procedures. While medical silicone tubing is a popular choice, alternatives like polyurethane tubing and fluoropolymer tubing also offer unique properties that may be better suited for certain applications. It is important to compare tensile strength, elongation values, and other physical attributes, such as flexibility and chemical compatibility, when choosing the right tubing.