The future of thin wall silicone tubing is poised for remarkable advancements, driven by continuous innovation and evolving industry demands. As technology progresses, the development of new materials and manufacturing processes promises to enhance the performance and versatility of silicone tubing.

Emerging applications in healthcare, sustainable solutions, and integration with smart technology are just a few of the exciting trends on the horizon. This article explores these future development trends, highlighting how thin wall silicone tubing is set to meet the challenges and opportunities of tomorrow.

![]()

BUY THIN WALL SILICONE TUBING HERE

Development Trends Of Thin Wall Silicone Tubing

The development trends of thin wall silicone tubing are influenced by the continuous need for more efficient and reliable products. With an emphasis on enhancing the tubing’s mechanical properties, the industry is exploring new formulations and composite materials to create products that can withstand harsher environments and more demanding applications. The integration of thin walls with these advanced materials offers the potential for lighter, more adaptable, and higher-performing tubing solutions.

Market dynamics, including mergers and acquisitions, are reshaping the thin wall silicone tubing industry, enabling companies to leverage synergies and foster innovation. The global market is seeing an uptick in demand, particularly in sectors where the tubing’s unique characteristics can provide a competitive edge. As a result, market growth is expected to continue, with companies like NewAge Industries leading the charge in developing next-generation thin wall silicone tubing products. Let’s explore the development trends of thin wall silicone tubing in detail:

Advancements in Material Technology

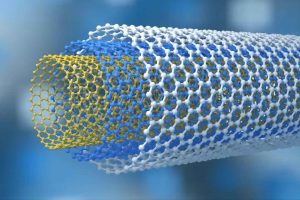

Material science plays a pivotal role in the future of thin wall silicone tubing, with ongoing research into polymers that enhance performance. Efforts aim to improve not only the mechanical properties of silicone but also its thermal stability and chemical resistance.

- Research focuses on enhancing mechanical properties, thermal stability, and chemical resistance.

- Development of hybrid materials and additives for specialized applications.

These advancements are crucial for industries like aerospace and automotive, where silicone composites are being developed to maintain structural integrity under extreme conditions.

- Silicone composites are crucial for aerospace and automotive industries.

- Expected outcomes include tubing that is more resilient, flexible, and functional across wider temperature and pressure ranges, broadening its applications.

Innovations in Manufacturing Processes

Innovations in manufacturing processes are instrumental in advancing the production of thin wall silicone tubing. Techniques such as precision extrusion and cross-linking are being refined to achieve greater control over the tubing’s dimensions and properties.

- Refinement of precision extrusion and cross-linking techniques.

- Enhancements aimed at improving product quality and process efficiency.

These advancements not only enhance the quality of the final product but also contribute to the efficiency and scalability of the production process. Manufacturers are also exploring the use of automation and robotics to further streamline production.

- Integration of advanced sensors and control systems for consistent quality.

- Adaptation to market demands, particularly in medical devices and high-precision applications.

BUY THIN WALL SILICONE TUBING HERE

Sustainable And Eco-Friendly Solutions

The drive towards sustainability is shaping the development of thin wall silicone tubing, with an emphasis on eco-friendly solutions.

- Manufacturers investigating bio-based silicones and recyclable materials.

- Efforts to minimize waste and energy consumption during production become a priority.

In addition to material choices, the longevity and reusability of silicone tubing contribute to its eco-friendly profile. Thin wall silicone tubing that can withstand repeated sterilization and harsh conditions without degrading helps reduce the need for frequent replacements, thereby lessening the environmental footprint of medical devices and other applications that rely on high-quality tubing.

Integration With Smart Technology

The integration of smart technology into thin wall silicone tubing presents new possibilities for monitoring and diagnostics.

- Embedding sensors within the walls of the tubing enables real-time data collection on flow rates, pressure, and temperature.

- This enhances the functionality of medical devices and industrial systems.

This convergence of materials science and electronics opens up avenues for more responsive tubing solutions.

- Advancements pave the way for predictive maintenance and process optimization.

- Smart tubing can alert users to potential issues before they escalate.

The use of smart technology in silicone tubing is expected to grow, driven by demand for more intelligent and interconnected systems across various industries.

BUY THIN WALL SILICONE TUBING HERE

Market Trends And Forecasts

The thin wall silicone tubing market is experiencing shifts influenced by the covid-19 pandemic, which has prompted increased demand in the medical sector. The versatility and safety profile of silicone tubing have led to its expanded use in critical medical devices, contributing to market growth. Forecasts indicate sustained expansion, with North America positioned as a significant market due to its advanced healthcare infrastructure and stringent regulatory standards.

Looking ahead, the adoption of thin wall silicone tubing is set to rise across several industries, driven by its favorable properties and adaptability. Market trends suggest a growing emphasis on customized solutions that cater to specific application needs, fostering a more diversified and innovative marketplace. As industries continue to evolve, the demand for high-performance silicone tubing is expected to propel market growth.

Challenges And Opportunities

The burgeoning demand for thin wall silicone tubing in medical devices presents both challenges and opportunities. The need for stringent quality control and compliance with regulatory standards poses a hurdle for manufacturers. However, this also opens opportunities for innovation in product design and quality assurance practices. Companies that can navigate these challenges and meet the high expectations of the medical industry are poised to gain a competitive edge.

Furthermore, the quest for more sustainable and environmentally friendly medical devices is prompting manufacturers to explore new materials and processes. This shift not only aligns with global sustainability goals but also presents a chance to differentiate products in the market. Those who can successfully integrate eco-friendly practices with the technical requirements of medical-grade tubing will likely emerge as leaders in this evolving landscape.

Wrap-Up!

As the curtain falls on the discussion of thin wall silicone tubing, it’s evident that the sector is on the brink of transformative growth, driven by players operating with a keen eye on innovation. Advancements in material properties and extrusion equipment are setting the stage for a new era where the performance of tubing will meet the rigorous demands of a variety of applications. The healthcare and medical industry, in particular, stands to benefit from these developments, as more precise wall thicknesses and enhanced durability translate into better outcomes for both providers and patients.