Stainless steel hoses are a premium choice for projects demanding robust performance in challenging conditions. Known for their ability to handle corrosive materials, stainless steel is a staple in industries such as oil and gas, pharmaceuticals, and automotive. By selecting stainless steel, professionals ensure longevity and reliability in their operations.

These hoses boast a construction that is inherently resistant to corrosion, making them ideal for transporting a wide range of substances without degradation. Their clear design allows for easy flow monitoring, adding an extra layer of safety and efficiency, which is especially critical in the pharmaceutical industry, where purity is paramount, and in the automotive industry, where precision is key. In this post, we will discuss the main features and benefits of SS clear hoses and why they can play an important role in your next project. Let’s continue reading!

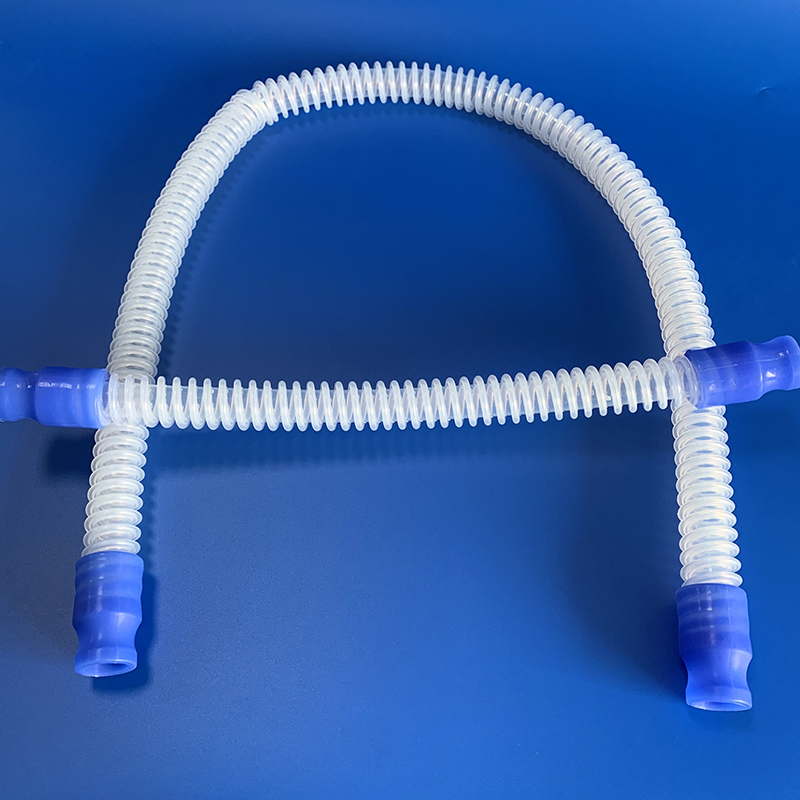

Stainless Steel Clear Hose Overview

![]()

Stainless steel clear hoses offer an unparalleled blend of durability and clarity, making them an essential component in various industrial applications. The presence of stainless steel fortifies its structural integrity, a material known for its capacity to withstand harsh environments and corrosive materials. This makes them particularly valuable in sectors like oil and gas, where the integrity of materials is non-negotiable.

In the pharmaceutical industry, the importance of contaminant-free processes elevates the value of stainless steel hoses, which maintain purity standards while resisting deterioration. Similarly, the automotive industry relies on these hoses for their ability to endure high temperatures and pressures, ensuring reliability and performance in critical applications.

The adaptability of stainless steel hoses’ adaptability to diverse functions is a testament to their design and construction. They cater to various pressures and temperatures while maintaining compatibility with numerous fittings and connectors. This versatility is why they are the go-to option for engineers and project managers seeking a dependable solution across multiple industrial applications.

SS Clear Hose Specifications

The specifications of stainless steel hoses are tailored to meet the exacting requirements of industries like oil and gas and the automotive industry. These hoses are engineered for high performance, emphasizing maintaining structural integrity under strenuous conditions.

Production Process

The production process of stainless steel hoses involves meticulous assembly to ensure superior quality and performance. Each component is selected and crafted precisely to create a hose that meets industry standards.

Vulcanization Process

The vulcanization process is a critical step in manufacturing rubber hoses, enhancing their strength and elasticity. This process imbues the hoses with the ability to withstand extreme temperatures, contributing to the numerous benefits of using stainless steel hoses, especially in the food and pharmaceutical industries.

Fabric

The fabric used in constructing stainless steel hoses is chosen for its strength and compatibility with its intended use. Its quality is paramount to the overall performance and longevity of the hose.

Steel Wire

The steel wire embedded within the structure of the hose fortifies its corrosion resistance, enabling it to endure harsh substances and maintain its integrity over time, a crucial factor in demanding environments.

Inner & Outer Wall

The inner and outer walls of silicone hoses are designed to be non-reactive and smooth to prevent buildup, ensuring a clean and efficient flow of materials.

Packing Length

The packing length of hoses is carefully calculated to accommodate transportation and installation requirements, ensuring efficiency and convenience for users.

Standard

Stainless steel hoses are produced following stringent industry standards, which dictate their quality, safety, and suitability for various applications.

Temperature Resistance

Stainless steel hoses are engineered to resist a wide range of temperatures, making them suitable for extreme heat or cold applications.

Daily Capacity

The daily production capacity for stainless steel hoses is optimized to meet the high demand from industries such as the automotive sector, which relies on their consistent quality and availability.

![]()

SS Clear Hose Benefits

Choosing stainless steel hoses for your project delivers distinct advantages, including enhanced performance in the automotive industry and beyond.

Pressure and Temperature Resistance

Stainless steel silicone tubing is designed for high-pressure applications where durability and reliability are paramount. They are an integral component in hydraulic systems, where they must sustain intense pressure without compromise.

Their construction also allows these hoses to withstand temperatures, ensuring functionality and safety in various operational conditions.

Corrosion Resistance and Durability

Silicone hoses are favored for their exceptional durability, reducing the need for frequent replacements. Their chemical resistance is a significant advantage in environments exposed to corrosive substances.

Conversely, rubber hoses may degrade more quickly in such conditions, demonstrating the superiority of silicone in terms of longevity and performance.

Flexibility and Manoeuvrability

One of the key advantages of stainless steel clear silicone hoses over traditional metal pipes is their superior flexibility. This allows for easy installation in tight spaces and complex systems without compromising the integrity of the hose. The flexibility of silicone hoses is attributed to their ability to maintain a consistent bend radius, ensuring that the hose does not kink or collapse when bent to conform to the contours of the installation environment.

Furthermore, the maneuverability of these hoses greatly simplifies maintenance and replacement processes. Unlike rigid metal pipes that require significant effort to modify or remove, stainless steel clear silicone hoses can be easily repositioned or rerouted, saving time and reducing labor costs. This is particularly beneficial in dynamic systems where frequent adjustments are necessary.

Enhanced Safety and Reliability

When it comes to safety and reliability, stainless steel clear silicone hoses are manufactured using high-quality materials that contribute to their exceptional durability. These hoses are designed to withstand harsh conditions without succumbing to wear, ensuring a long service life. In critical applications such as fire protection systems, where failure is not an option, stainless steel hoses offer a trustworthy solution that can be relied upon in emergencies.

Stainless steel hoses also enhance safety by minimizing the risk of leaks and bursts under extreme pressure. Their ability to maintain structural integrity at pressures up to 16 times their normal operating range is a testament to their robust construction. This level of reliability is crucial in systems where performance and safety cannot be compromised.

Versatility and Compatibility

Stainless steel hoses are unmatched in their versatility, making them suitable for a wide range of applications. In the food and beverage industry, for example, their non-reactive nature ensures that they do not impart any taste or odor, maintaining the purity of the products being conveyed. Additionally, stainless steel hoses are renowned for their compatibility with various chemicals and fluids, making them a versatile choice for many sectors.

Moreover, the clear design of these hoses allows for easy visual inspection of the fluid flow, which is critical in processes where monitoring is essential. Whether it’s transferring sensitive materials or withstanding aggressive cleaning agents, stainless steel clear silicone hoses offer the adaptability needed to meet the demands of various industries.

Cost-Effectiveness

Despite the initial investment, the price of stainless steel clear hose offers significant cost savings over the long term. Their durability and resistance to wear reduce the frequency of replacement, which, when combined with minimal maintenance requirements, results in a lower total cost of ownership. Additionally, the ease of installation and flexibility reduce labor costs and downtime, enhancing cost-effectiveness.

Furthermore, using hose clamps designed for stainless steel hoses ensures a secure and leak-proof connection, contributing to the system’s overall efficiency and economy. These hoses are a financially prudent choice for any project because they prevent costly leaks and ensure system integrity.

![]()

SS Clear Hose Applications

Stainless steel clear silicone hoses are utilized across various industries due to their exceptional performance characteristics. From industrial manufacturing to high-purity processing, these customized silicone tubings provide reliable and efficient fluid transfer solutions that cater to the specific needs of different sectors. With their robust design and versatile applications, stainless steel hoses are valuable in many operational contexts.

Industrial Applications

In the industrial sphere, steel wire hose pipe is prized for its resistance to corrosion, which is essential in environments where exposure to harsh chemicals is common. The ability to resist rust and corrosion extends the lifespan of these hoses and ensures the integrity of the substances being transported. Whether they are used for chemical transfer, steam delivery, or water processing, the corrosion-resistant nature of stainless steel hoses makes them an ideal choice for demanding industrial applications.

Automotive and Transport Industries

The automotive and transport industries benefit significantly from using stainless steel clear silicone hoses, which can handle a variety of fluids and pressures. These hoses are designed to withstand the high-stress conditions of automotive systems, enduring temperatures and pressures exceeding 30 times their normal operating range. Their resilience ensures reliable performance in vehicles and transportation equipment, contributing to safety and efficiency on the road.

Heating, Ventilation, and Air Conditioning (HVAC) Systems

Stainless steel clear silicone hoses play a pivotal role in HVAC systems, where they are used for their ability to withstand a wide range of temperatures and pressures. Their flexibility facilitates easy installation and maintenance in ductwork, while their durability ensures long-term reliability. The clear design also allows technicians to monitor for any blockages or buildup, maintaining the system’s efficiency and performance.

Aviation and Aerospace

In the demanding field of aviation and aerospace, stainless steel clear silicone hoses are essential for their high-pressure capabilities and resistance to extreme temperatures. The durability and reliability of these hoses are critical in applications where failure is not an option. They are commonly used in fuel, oil, and hydraulic systems, where their performance can be the difference between a successful mission and a compromised one.

Research and Development Facilities

Research and development facilities rely on steel hose wire pipes for their precision and reliability in experimental setups. These hoses can handle a variety of chemicals and gasses without contamination, which is crucial for maintaining the integrity of scientific experiments. Their clear design allows for easy monitoring of fluid flows, ensuring accurate data collection and analysis.

Biotechnology and Pharmaceutical Industries

The biotechnology and pharmaceutical industries require hoses that meet stringent cleanliness and non-contamination standards. Stainless steel clear silicone hoses are ideal for these environments as they can be easily sterilized and do not leach harmful substances. Their transparency allows for visual inspection of the contents, ensuring that the highest quality standards are maintained throughout the production and research processes.

![]()

Wrap-Up!

Opting for a stainless steel clear silicone hose equips any project with robust resistance properties, ensuring performance under the rigors of demanding environments. These hoses are designed to maintain structural integrity while exposed to the harsh conditions of industrial processes. The integration of stainless steel fittings further enhances their ability to withstand corrosive substances and extreme pressures, making them an indispensable asset in various applications.

The selection of a stainless steel clear silicone hose is a testament to a commitment to quality, safety, and efficiency. Its ability to resist temperature fluctuations and impressive durability make it a reliable choice for professionals anticipating dynamic industrial landscape challenges. These hoses offer a blend of versatility and performance that is hard to surpass, making them a superior option for any critical project.